Description

VISIC620: Advanced Vision Sensor System

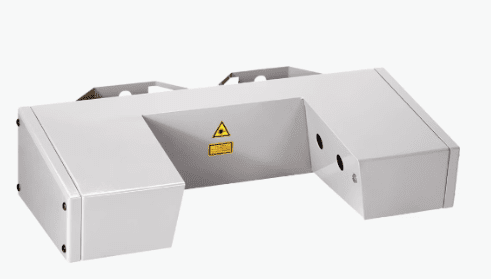

The VISIC620 is a state-of-the-art vision sensor system designed to deliver high-performance image analysis and inspection capabilities for a variety of industrial applications. Engineered with precision and versatility in mind, the VISIC620 ensures exceptional performance in quality control, process monitoring, and automation tasks, making it an essential tool for optimizing production efficiency and maintaining high standards of product excellence.

Key Features

High-Resolution Imaging

To start with, the VISIC620 boasts advanced high-resolution imaging technology. The system is equipped with cutting-edge cameras that capture clear and detailed images, providing accurate data for thorough analysis. This high-definition imaging is crucial for inspecting fine details and ensuring the quality of components and products.

Advanced Image Processing

Additionally, the VISIC620 incorporates sophisticated image processing algorithms. These algorithms enhance the system’s ability to detect defects, measure dimensions, and recognize patterns with high accuracy. As a result, users can rely on the VISIC620 for comprehensive and reliable inspection, which helps in maintaining high product quality and efficiency.

Real-Time Analysis

Moreover, the VISIC620 features real-time image processing capabilities. This allows for immediate feedback and rapid identification of issues as they occur. Real-time analysis supports quick adjustments and helps in maintaining optimal operational conditions, reducing potential downtime and improving overall productivity.

Flexible Configuration Options

Furthermore, the VISIC620 offers flexible configuration options to meet diverse application requirements. Users can easily adjust settings such as image resolution, frame rate, and analysis parameters through an intuitive interface. This adaptability makes the VISIC620 suitable for a wide range of inspection tasks and environments.

Robust and Durable Design

In addition, the VISIC620 is designed to withstand the rigors of industrial environments. Its robust construction ensures reliable performance even in challenging conditions, such as high temperatures, dust, and vibrations. This durability contributes to the system’s long-term reliability and reduces maintenance needs.

User-Friendly Interface

The VISIC620 is also equipped with a user-friendly interface that simplifies operation and management. The high-resolution display provides clear visual feedback, while the intuitive controls facilitate easy configuration and adjustments. This design enhances usability and ensures that the system is accessible to operators with varying levels of experience.

Seamless Integration

Another notable feature of the VISIC620 is its seamless integration with existing automation systems. The sensor supports various communication protocols, including Ethernet, USB, and digital I/O. This compatibility allows for smooth connectivity with other equipment and control systems, enhancing overall system interoperability.

Specifications

Imaging Technology

- Camera Type: High-Resolution Vision Sensor

- Resolution: High-Definition for Detailed Inspection

- Frame Rate: Adjustable for Real-Time Processing

Image Processing

- Algorithms: Advanced Algorithms for Accurate Analysis

- Functions: Defect Detection, Dimension Measurement, Pattern Recognition

- Performance: Real-Time Analysis with Immediate Feedback

Design and Durability

- Construction: Robust and Industrial-Grade

- Resistance: High Temperatures, Dust, Vibrations

- Maintenance: Low Maintenance Requirements

User Interface

- Display: High-Resolution for Clear Visual Feedback

- Controls: Intuitive and Easy to Use

- Operation: Simplified Configuration and Management

Connectivity

- Protocols: Ethernet, USB, Digital I/O

- Integration: Seamless with Existing Automation Systems

- Data Transfer: Efficient and Flexible

Installation and Setup

Step-by-Step Guide

To begin, carefully unpack the VISIC620 and verify that all components are present and undamaged. Install the system in a location that meets operational and environmental requirements, ensuring proper alignment with the inspection area. Connect the sensor using the provided cables and configure it through the user-friendly interface. Adjust the settings according to your specific application needs and perform a thorough system check to ensure proper functionality.

Troubleshooting

If any issues arise, consult the troubleshooting section of the user manual for guidance. Common problems, such as connectivity issues or image quality concerns, can often be resolved with simple adjustments. For more complex challenges, our dedicated customer support team is available to provide expert assistance and ensure that your system operates smoothly.

Benefits

Enhanced Quality Control

The VISIC620 enhances quality control processes by providing detailed and accurate image analysis. This capability ensures that defects and anomalies are detected early, maintaining high standards of product quality and reducing waste.

Increased Efficiency

With real-time processing and flexible configuration options, the VISIC620 improves operational efficiency. Immediate feedback and adaptable settings enable quick adjustments and process optimizations, leading to streamlined operations and minimized downtime.

Durability and Reliability

The system’s robust design ensures reliable performance even in harsh industrial conditions. Its resistance to high temperatures, dust, and vibrations minimizes maintenance needs and supports long-term operational stability.

Ease of Use

The user-friendly interface of the VISIC620 makes system operation and management straightforward. Clear visual feedback and intuitive controls enhance usability, making it accessible to operators with varying levels of experience.

Flexible Integration

The VISIC620 supports various communication protocols, allowing for seamless integration with existing automation systems. This flexibility enhances system interoperability and facilitates efficient data management and connectivity.

Customer Reviews

Olivia J.: “The VISIC620 has revolutionized our quality control processes. Its high-resolution imaging and real-time analysis capabilities have significantly improved our defect detection and overall efficiency.”

Ethan M.: “We’ve been using the VISIC620 for several months now, and it has exceeded our expectations. Its robust design and ease of use make it a reliable addition to our production line.”

Isabella T.: “The VISIC620 provides excellent performance and flexibility. Its ability to integrate seamlessly with our existing systems and its high durability make it an invaluable tool for our operations.”

Why Choose VISIC620?

In summary, the VISIC620 vision sensor system combines high-resolution imaging, advanced image processing, and a robust design to deliver superior performance across a variety of industrial applications. Its real-time analysis, flexible configuration, and user-friendly interface make it an excellent choice for enhancing quality control, optimizing processes, and ensuring operational efficiency. By selecting the VISIC620, you invest in a system that supports accurate analysis, reliable performance, and long-term success.

Check our other SICK Products: https://midmacinternational.com/product-category/instrumentations/sick/