YOKOGAWA Movement Monitoring

YOKOGAWA Movement Monitoring

YOKOGAWA Movement Monitoring

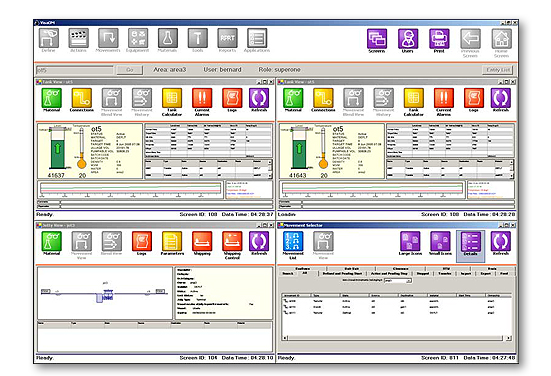

A core element of the model-based mPower application suite, VisaOM (Movement Monitoring) is designed to track raw materials, feed-stocks and products through an entire plant for continuous and batch-based processes.

Incorporating mass balancing techniques VisasOM interprets raw measurements and other data in terms of movements of material inside the refinery. VisaOM is able to accurately track movements, even when there are multiple flows in and out of individual tanks. VisaOM records data on material stocks, material movements and equipment usage.

VisaOM provides operators with accurate live information on the material movements between tanks and other process units. A comprehensive alarm system is provided to warn operators of abnormal and hazardous operations. Using VisaOM operators can supervise the equipment safely, accurately and productively. Information can be output in reports for use by human or computer systems.

Introducing Yokogawa’s Movement Monitoring Solution – Revolutionizing Precision and Safety in Industrial Operations. Yokogawa sets a new standard in industrial motion monitoring with a state-of-the-art system designed to enhance precision, ensure safety, and optimize overall operational efficiency.

**Key Features:**

1. **Real-time Motion Analysis:**

Yokogawa’s Movement Monitoring Solution provides real-time analysis of industrial motion, offering unparalleled insights into the dynamics of moving components. Monitor machinery and equipment with precision, allowing for immediate corrective actions and minimizing downtime.

2. **Advanced Vibration Detection:**

Elevate your predictive maintenance strategy with advanced vibration detection capabilities. The system utilizes cutting-edge sensors to detect and analyze vibrations, enabling early identification of potential issues and preventing costly equipment failures.

3. **Customizable Monitoring Parameters:**

Tailor the monitoring parameters to align with the unique characteristics of your machinery. Yokogawa’s solution allows users to customize monitoring settings, ensuring that the system is finely tuned to the specific requirements of diverse industrial processes.

4. **Seamless Integration with PLCs:** Achieve a seamless integration with Programmable Logic Controllers (PLCs) for enhanced control and monitoring. Yokogawa’s Movement Monitoring Solution interfaces seamlessly with existing control systems, providing a unified platform for comprehensive motion analysis.

**Technical Excellence:**

– **Precision Accelerometers:** Benefit from Yokogawa’s high-precision accelerometers that deliver accurate motion data. The solution is equipped with sensors designed to withstand harsh industrial environments while providing reliable and precise measurements.

– **Machine Learning Algorithms:** Harness the power of machine learning algorithms for predictive analytics. Yokogawa’s solution employs advanced algorithms to analyze historical motion data, predict potential issues, and optimize maintenance schedules, reducing unplanned downtime.

– **Wireless Connectivity:**

Embrace the flexibility of wireless connectivity. The Movement Monitoring Solution by Yokogawa offers wireless communication options, reducing the need for complex cabling and facilitating easy deployment in diverse industrial settings.

In conclusion, Yokogawa’s Movement Monitoring Solution represents a groundbreaking advancement in industrial motion analysis. Embrace precision, enhance safety, and optimize operational efficiency with Yokogawa – where innovation meets motion monitoring excellence.

Check out our new other YOKOGAWA Products https://midmacinternational.com/product-category/instrumentations/yokogawa/